What is the difference between beam and bar

Voortman created Raptor 3DCAD/CAM Software. It allows users to program faster and with greater accuracy. The 3D platform lets you inspect, modify, export and export information directly. This combined with Voortman CNC technology allows for maximum fabrication capacity.

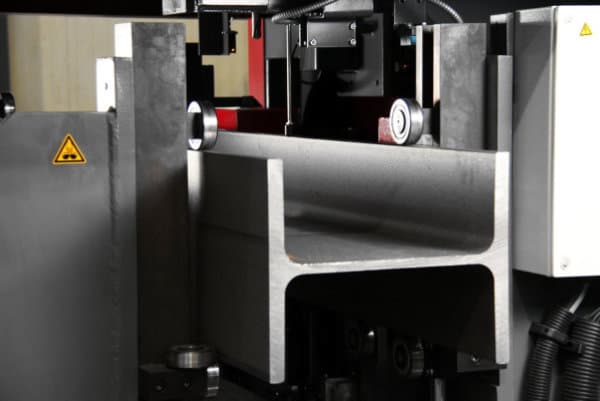

The CNC Beam Drill Line not just drills holes in any profile of steel in a fraction the time it takes, but also marks the locations for all your welded attachments.